Piloting an Innovative New Carbon Capture Technology

Capture and reuse CO2 to reduce your carbon footprint

Although natural gas is the cleanest of the fossil fuels, its use still contributes to greenhouse gas (GHG) emissions. CenterPoint Energy, as a leader in the energy industry, has a vested interest in protecting the environment, which includes a continued and long-term focus on reducing GHG emissions from our operations.

A Solution

As the world looks toward energy efficiency and renewable energy sources to reduce GHG emissions, there is also a place for other clean energy technologies, such as carbon capture and storage or reuse, which can capture the carbon dioxide (CO2) emissions produced from the use of natural gas, preventing the CO2 from entering the atmosphere. It is also one of the few carbon abatement technologies that removes CO2 from the atmosphere.

Capture technologies enable the separation of CO2 from natural gas during either pre- or post-combustion. The captured CO2 can then be used to manufacture fuels, building materials and more.

The Innovator

CleanO2 Carbon Capture Technologies (operating as CleanO2) is a Canadian company that invented the world’s first decentralized commercial carbon capture device to lower GHG emissions in the heating industry and reduce energy demand through heat recovery. Its mission is to reduce energy costs, capture and convert CO2 into a chemical byproduct while lowering GHG emissions, and reduce the cost of operations through the sale of the byproduct. Light industrial and commercial customers that have a CARBiNXTM device installed in their natural gas-powered heating and water heating systems can share revenue byproduct sales.

The Technology

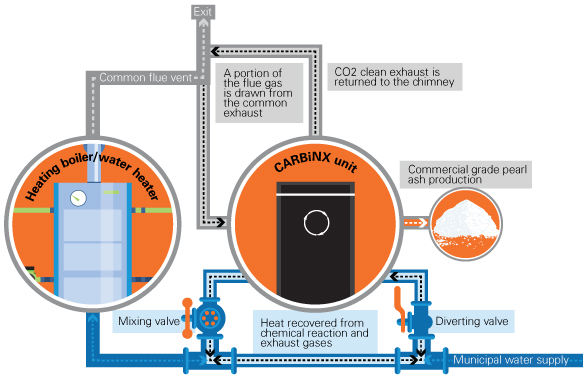

Each CARBiNX device, which is about the size of two mid-sized refrigerators, is attached to natural gas-powered boilers or water heaters to reduce both energy use and greenhouse gas emissions. The device takes a portion of waste flue gas containing CO2 and passes it through a reaction chamber, where it reacts with a carbon-reduction chemical to create pearl ash. This valuable byproduct can be used to produce hand soap, fertilizer, and other commercial products where the CO2 will stay captured even after use. Waste heat from the flue gas and chemical reaction is then used to preheat water for a water heater.

The energy savings comes from the way the unit transfers the thermal energy that is produced from the patented process of capturing CO2. The heat generated from the process is captured with a heat exchanger, and it and the heat recovered from the flue gas are used to preheat a building’s domestic water supply.

CleanO2 Heat Recovery and Carbon Capture Process

The Potential Benefits

Cost Savings: Clean02 estimates that the CARBiNX carbon capture device can decrease energy consumption by up to 20 percent, depending on boiler size, efficiency and hot water consumption.

Emissions Reductions: Clean02 has indicated that increased energy efficiency, coupled with carbon capture, may reduce CO2 emissions by more than 20,000 pounds annually per unit. To give you an idea of how much that is, 20,000 pounds of CO2 would fill ten 1,250-square-foot, single-story houses.

Carbon Reuse: Each CARBiNX device can create up to 14,000 pounds of pearl ash per year, according to Clean02, which can be used to manufacture a variety of commercial products such as soap and fertilizer, and as an additive for concrete, plastics, glass and biofuel.

The Pilot

CenterPoint Energy is working with CleanO2 to field test its new, innovative technology, which aligns with CenterPoint Energy’s Minnesota energy efficiency goals to help customers

reduce costs, increase efficiency and minimize their environmental impact. The 12-month research pilot will monitor and measure the energy savings and CO2 reductions that light industrial and commercial companies experience with the installation of a CARBiNX carbon capture device. CenterPoint Energy is funding the installation and maintenance of each unit.